Inventory Management Systems: A Deep Dive for Experts

The rise of omnichannel commerce has introduced new challenges in inventory management, requiring businesses to organise inventory across numerous sales channels and stock locations.

For businesses in inventory-intensive industries, such as retail and manufacturing, maintaining the optimal level of stock for each channel and location is critical.

A shortage of inventory can lead to lost revenue and disappointed customers, while a surplus of inventory can impact profit margins through the cost of storage and insurance, the risk of damage, theft and spoilage, and the need to discount or destroy unsold stock.

Finding the perfect balance requires sophisticated tools to optimise the flow of goods and ensure supply meets demand as efficiently as possible.

In this article, we explore the role an Inventory Management System plays in modern businesses and offer solutions and best practices to help you successfully navigate the complex world of inventory management.

Table of contents

Understanding Inventory Management Systems

Definition and core concepts

Importance to modern businesses

The role in supply chain management

Why companies need Inventory Management Systems

Enhancing efficiency and accuracy

Cost reduction and profit maximisation

Alignment with business strategy

The evolution and impact of technology

Historical developments

State-of-the-art features and integrations

Global strategies and compliance

Cross-border considerations

Regulatory and ethical aspects

Advanced inventory optimisation techniques

Predictive analytics and machine learning

Real-time tracking and lean principles

Challenges, solutions and best practices

Common pitfalls and how to avoid them

Security, data quality and change management

Success stories in various industries

Emerging trends and future outlook

Conclusion: Navigating the complex world of inventory management

Key takeaways for experts

Resources and next steps

Understanding Inventory Management Systems

To truly grasp their significance, it’s essential to delve into how an Inventory Management System operates and the role it plays in today’s commerce environment.

Definition and core concepts

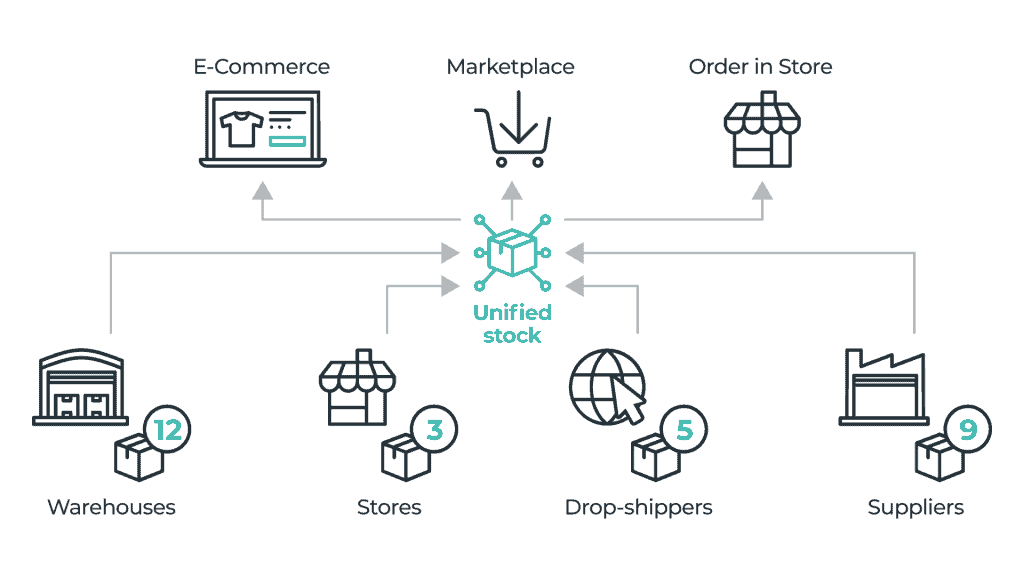

An Inventory Management System is a software application that enables businesses to track, organise and optimise the flow of goods throughout their supply chain, ensuring the right products are available in the right quantities, at the right time and in the right place.Successful inventory management relies on inventory visibility, or stock unification, which gives businesses a complete, accurate and real-time view of their inventory and its movements across the entire network. This is based on several key concepts:

- Stock quantities: Inventory levels are imported from all sources, including manufacturers, suppliers, dropshippers, warehouses, 3PLs, stores, wholesalers, etc.

- Stock disposition: This status or condition of stock – for example, an item may be damaged, missing, or at a certain point in the manufacturing process – with the ability to exclude dispositions from some or all sales channels.

- Stock segmentation: Stock can be allocated to specific markets or channels based on ownership or sales strategy.

- Stock reservations: Once a customer order is placed, the stock required to fulfil that order is reserved and made unavailable for sale.

- Future stock: Stock that is on order or in transit and due to be received by a stock location at a given date. Future stock can be made available to customers for purchase with accurate delivery times based on their expected receipt date and available fulfilment options.

- Safety buffers: An additional quantity of stock set at each location and at a global level to account for shortages during preparation (due to missing or damaged items).

This information is aggregated into a unified stock, which becomes the central point of reference for enterprise-wide inventory.

Importance to modern businesses

In today’s fast-changing and highly competitive commerce environment, Inventory Management Systems play a pivotal role in the success and sustainability of a business.

By automating inventory management, businesses can minimise human error and make data-driven decisions regarding purchasing, production and distribution, ensuring the right amount of stock is available to meet demand.

This helps to prevent stockouts, where products are unavailable when customers want to purchase them, as well as overstocking, which ties up capital and leads to increased carrying costs and decreased profit margins.

Finally, it allows businesses to align their inventory management strategies with overall business objectives. For instance, companies can choose to focus on minimising costs, maximising service levels, or reducing carbon emissions.

The role in supply chain management

The Inventory Management System has three key functions to support the seamless flow of goods throughout the supply chain:

- Demand forecasting and planning: An Inventory Management System offers forecasting capabilities to accurately plan production, procurement, replenishment and distribution, ensuring products are available when and where they’re needed.

- Supplier relationship management: Real-time insight into inventory levels, customer demand, lead times and supplier reliability enables businesses to maintain positive, collaborative relationships with suppliers.

- Supply chain optimisation: An Inventory Management System helps to reduce excess stock and associated carrying costs, improving cash flow and profitability. It also informs decisions regarding stock allocation, replenishment, transfers and order fulfilment, reducing transportation costs, minimising stockouts and improving the customer experience.

Why companies need Inventory Management Systems

Now that we have a comprehensive understanding of the Inventory Management System, let’s explore why it’s essential for any business dealing with inventory, regardless of size or industry.

Enhancing efficiency and accuracy

Automated tracking: Automating the tracking of inventory and orders reduces the need for manual data entry, saving time and minimising the risk of human error.

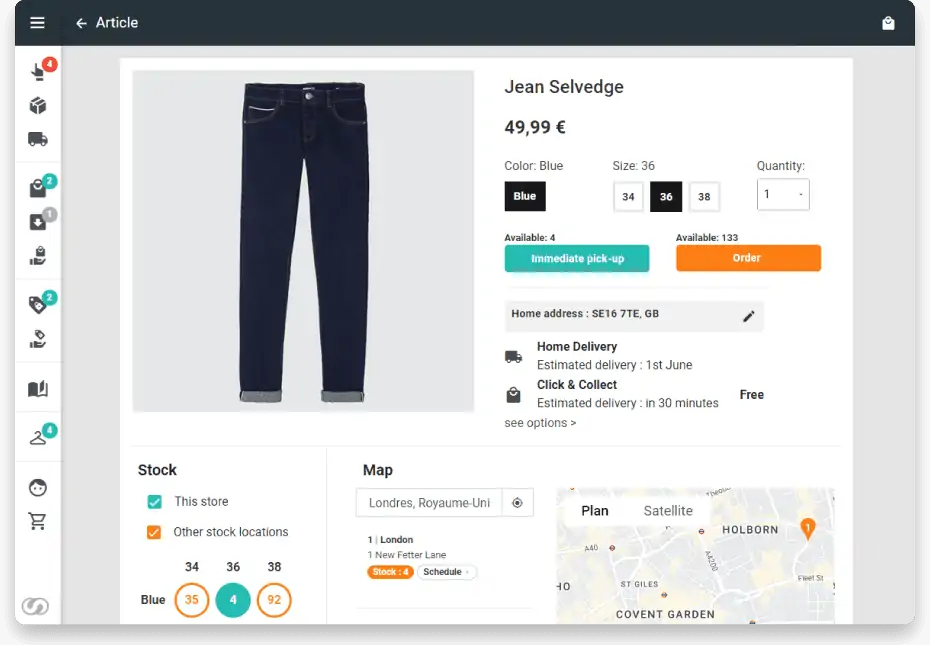

Real-time visibility: Key performance indicators are updated as soon as inventory moves and orders are processed. This is especially important in industries with rapidly changing demand patterns or precarious supply chains.

Order orchestration: Each order is allocated to the best location to fulfil it based on stock levels, turnover, staff capacity, proximity to the customer, etc. to minimise stockouts and overstock situations, improve delivery times and reduce transportation costs.

Cost reduction and profit maximisation

Lower carrying costs: By effectively managing inventory levels, businesses can avoid overstocking, which leads to increased storage and insurance costs. With capital no longer tied up in excess inventory, businesses have more cash on hand to invest in growth or weather economic downturns.

Improved sales opportunities: Effective inventory management also prevents stockouts, which can result in lost sales and dissatisfied customers. With optimal product availability at each location, businesses can service every purchase intention and improve the customer experience.Minimised obsolescence: Inventory optimisation helps businesses sell through stock faster, reducing the need for discounting. Tracking product shelf life and usage also helps minimise depreciation and the risk of obsolescence, reducing waste and losses due to expired or outdated goods.

Alignment with business strategy

Strategic flexibility: Businesses can easily adapt their inventory strategies to changing market conditions and customer expectations, whether it’s responding to sudden spikes in demand, cost-cutting measures in an economic downturn, or adapting to environmental regulations.

Service-level optimisation: Businesses can align inventory levels with their customer experience objectives. High-service industries, such as luxury fashion, often prioritise product availability in stores, while cost-driven businesses focus on lean inventory practices.

Data-driven decision-making: An Inventory Management System equipped with business intelligence can provide valuable data and actionable insights to inform strategic decisions. This approach enhances a company’s ability to respond to market dynamics quickly and effectively.

The evolution and impact of technology

Inventory Management Systems have come a long way through advancements in technology. Let’s explore the key developments that have shaped inventory management today.

Historical developments

Inventory Management Systems date back centuries, when merchants relied on manual record-keeping before the advent of computers revolutionised inventory management. Here are some key historical milestones:

- Manual records: Businesses maintained ledger books to record inventory levels manually.

- Barcode scanning: The introduction of barcode technology in the 1970s made inventory tracking faster and more accurate.

- Spreadsheets: In the 1980s, spreadsheet software like Microsoft Excel was used by businesses for inventory tracking and basic calculations.

- Early inventory software: Specialised inventory management software emerged in the 1990s with features like SKU tracking and reorder point calculations.

- Cloud-based systems: The 21st century brought with it cloud-based Inventory Management Systems, offering real-time visibility and collaboration.

State-of-the-art features and integrations

Leading Inventory Management Systems offer advanced capabilities and seamless integrations that enhance their functionality further:

- Cloud-based platforms: Cloud-based Inventory Management Systems provide accessibility from anywhere, regular updates and scalability to accommodate growing businesses.

- Integration with ERP: Integration with Enterprise Resource Planning (ERP) systems ensures the seamless flow of data between other business functions, including finance and procurement.

- E-commerce integration: For businesses with online sales channels, Inventory Management Systems must integrate with e-commerce platforms to manage both physical and online inventory.

- Mobile applications: Mobile apps allow for on-the-go inventory management, making it easier for warehouse and store teams to track and manage inventory anywhere.

- AI and machine learning: Predictive analytics and machine learning algorithms help businesses identify trends, forecast demand and continually optimise inventory management.

- Internet of Things: IoT devices enable real-time tracking of inventory through sensors and RFID tags for increasingly accurate data and visibility.

Global strategies and compliance

As businesses expand globally, they must consider the unique challenges related to inventory management across borders and within each market.

Cross-border considerations

Customs and duties: When operating in multiple countries, businesses need to account for customs duties, taxes, and import/export regulations, which can impact inventory costs.

Currency exchange: Fluctuating exchange rates can affect the value of inventory in different regions, requiring businesses to implement currency management strategies.

Shipping and logistics: Cross-border operations involve complex logistics, and businesses must optimise shipping routes, lead times and carriers for efficient inventory flow.

Regulatory and ethical aspects

Environmental compliance: Many countries have legislation regarding carbon emissions, as well as the handling and disposal of certain types of inventory, such as hazardous materials or electronic waste.

Ethical sourcing: Companies must consider the ethical sourcing of materials, especially in industries like fashion and electronics, where concerns about labour conditions and environmental impact are prevalent.

Data privacy: Global operations necessitate adherence to data privacy regulations in various regions, requiring careful management of customer and inventory data.

Advanced inventory optimisation techniques

To stay competitive in the ever-evolving business landscape, companies are adopting advanced inventory optimisation techniques enabled by technology.

Predictive analytics and machine learning

Demand forecasting: Predictive analytics uses historical data and machine learning algorithms to forecast demand with greater accuracy, minimising overstock and stockout situations.

Seasonal demand management: Predictive analytics can identify seasonal trends, allowing businesses to prepare for increased or decreased demand during specific times of the year.

Dynamic reordering: Machine learning can analyse real-time data and adjust reorder and replenishment points dynamically to maintain optimal stock levels.

Real-time tracking and lean principles

RFID and IoT: Real-time tracking through RFID and IoT devices provides instant visibility into inventory movements, allowing for swift responses to changes in demand or supply.

Lean inventory practices: Lean principles aim to eliminate waste in inventory management. Real-time data enables lean practices by reducing excess inventory and optimising production processes.

Continuous improvement: With real-time data, businesses can identify inefficiencies and bottlenecks in their inventory management processes and continuously improve them.

Challenges, solutions and best practices

Implementing and maintaining an effective Inventory Management System is not without challenges. Here are the most common hurdles businesses need to navigate.

Common pitfalls and how to avoid them

Inaccurate data: Relying on inaccurate data can lead to poor decision-making. Ensure data accuracy through regular audits and reconciliations.

Lack of automation: Manual processes are prone to errors and inefficiencies. Invest in automation to streamline operations and reduce reliance on manual input and intervention.

Inflexible systems: Inventory Management Systems built on Monolithic architectures can be complex to maintain. Choose an agile, composable system where new capabilities can be added at speed to align with your specific business needs.

Poor communication: Lack of communication between relevant departments can lead to misalignment in inventory strategies. Create cross-functional teams with regular communication channels to ensure your Inventory Management System is set up for mutual success.

Security, data quality and change management

Data security: Protect sensitive inventory data from unauthorised access by implementing robust cybersecurity measures and access controls.

Data quality assurance: Regularly verify data accuracy and integrity through data validation and data cleansing processes.

Change management: Implementing new systems and ways of working can often face resistance from employees. Develop a plan that includes training and support to ensure a smooth transition.

Compliance and regulatory requirements: Stay updated on industry-specific regulations and ensure that your Inventory Management System complies with data privacy and other relevant laws.

Case studies and innovations

Let’s explore some success stories from various sectors and the trends that are shaping the future of inventory management.

Success stories in various industries

INTERSPORT has long prioritised keeping stock in stores, rather than in warehouses, to meet the needs of local customers. By unifying stock across its store network to display on its website, INTERSPORT has reduced online stockouts and improved the customer experience.

RougeGorge has an extensive assortment of lingerie in various shapes, colours and sizes, and it simply isn’t possible to hold all variations in a single store or warehouse. Inventory visibility allows all available products across all locations to be ordered online or in-store, maximising sales opportunities.

Petit Bateau has always manufactured children’s clothing made to last and wanted to bring this same environmental focus to its supply chain. By unifying warehouse and store inventory, Petit Bateau can now optimise the flow of stock to reduce carbon emissions, meeting customer expectations for both speed of service and sustainability.

Jigsaw continually updates its unified stock during order fulfilment. When a store is unable to fulfil an online order (for example, when an item is found to be sold, reserved, damaged or missing), the discrepancy is recorded, and stock is automatically reconciled without waiting for the end-of-season stocktake.

Emerging trends and future outlook

Sustainability: Businesses are increasingly focusing on sustainable inventory management practices, including reducing packaging and product waste, and minimising carbon emissions.

3D printing: 3D printing has the potential to disrupt traditional inventory models by enabling on-demand manufacturing of products.

Artificial intelligence: AI-driven inventory management will continue to evolve, with more advanced algorithms and predictive capabilities.

Conclusion: Navigating the complex world of inventory management

Inventory Management Systems are vital tools for businesses aiming to optimise their operations, reduce costs and stay competitive in today’s global marketplace.

Key takeaways for experts

In the complex and ever-evolving realm of inventory management, technology and supply chain leaders should keep these critical lessons in mind:

- Data is king: The accuracy and integrity of your inventory data are non-negotiable. Regularly audit and validate data to ensure it remains reliable.

- Automation unlocks efficiency: Embrace automation to streamline operations, reduce human errors and enhance overall efficiency.

- Strategic alignment matters: Align your inventory management strategy with your broader business goals for optimal results.

- Stay agile: Be ready to adapt to new technologies, sales channels and customer demands with a highly flexible and completely composable tech stack.

Resources and next steps

You’re now well on your way to conquering the complex world of inventory management. If you’d like to dive deeper into the subjects discussed in this article, here are some valuable resources to explore:

READ: Fighting stockouts with the Inventory Management System

READ: How the Business Intelligence Suite helps reduce residual stock

READ: Why modern businesses are switching to MACH

READ: How can retailers protect the planet and their bottom line?

WATCH: Inventory Management Systems & omnichannel retail: ROI, profits, how it works

DOWNLOAD: Your free Inventory Management System RFP template

Ready to take the next steps on your inventory management journey? Get in touch to book an exploratory call with one of our experts.